Bisedo me Ava - Konsulentja juaj AI e biznesit

Përshëndetje, unë jam Ava, udhëzuesi juaj i AI për të suoerkarikuar biznesin tuaj!

Pavarësisht nëse jeni duke drejtuar tashmë një biznes ose ëndërroni të filloni një të tillë, unë jam këtu për t'ju ndihmuar ta ktheni vizionin tuaj në realitet duke përdorur freelancer të fuqiyuar me AI. Ndani qëllimet tuaja të biznesit dhe së bashku, ne do të krijojmë një projekt për të cilin mund të konkurrojnë freelancerët tanë të talentuar. Le ta bëjmë realitet vizionin tuaj!

Unë kam një biznes

Unë jam duke filluar një biznes

Ndodhi një gabim ndërsa po dërgonim bisedën në email-in tuaj.

Mund ta ruash bisedën vetëm një herë në orë. Ju lutem provojeni përsëri më vonë.

Biseda është shumë e shkurtër. Vazhdo të flasësh me Ava për të mundësuar ruajtjen.

The complete guide to building an electronics product

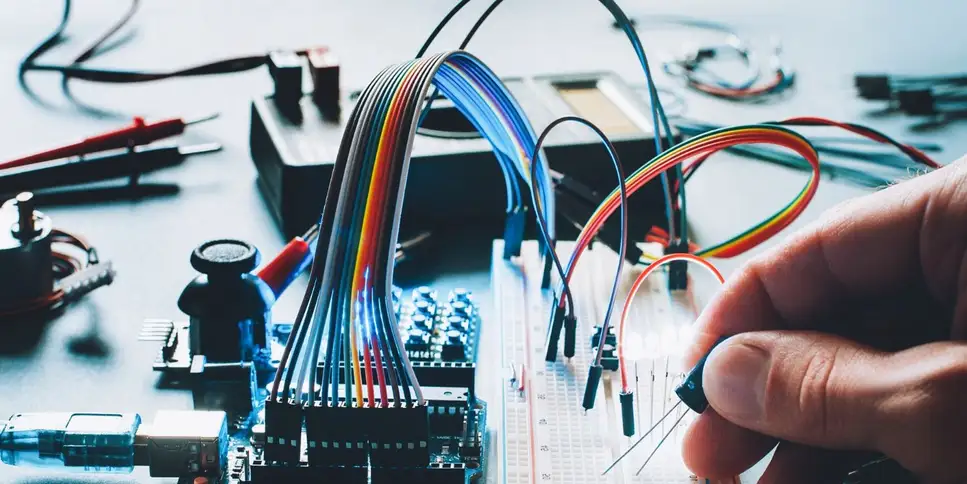

So you have a great idea for the next big tech gadget? Don't know where to start? We'll walk you through every step of the process

9 pri 2020 • 8 minutë lexim

Content Writing | Designing | Web Development

Kopja te kujtesa e fragmenteve nuk u krye, provo sërish pasi të kesh përshtatur lejet.

U kopjua në tabelë

The 7 steps you need to take to build your electronics product

So you've finally zeroed in on the idea for that next great electronics product. Good for you.

You know it's going to be a hit. You're certain that people will buy it like the next iPhone. And you're on your way to becoming the next Steve Jobs.

Now the only thing that's left to do is design the product, a task that is easier said than done. Designing an electronics product from scratch takes time, patience and perseverance.

Not to mention the technical know-how that is needed for the task. It used to be that no one but an engineer well-versed in the intricacies of the electronics design and development process could dare to bring a new product to market.

However, in 2020, the job of designing a new electronics product is certainly simpler than before. In fact, you don't even need to be an engineer to get the job done.

In today's post, we are going to walk you through the steps that you need to take to develop a new electronics product. Be advised, this is not for the faint of heart. But if you are determined to get your new product up and running, then there's no better time than now to get going.

Let's begin.

The seven steps to success

As mentioned before, designing an electronics product can be complex. But it's also a rewarding journey, provided you know the right path.

In this section, we are going to set-up a seven-step plan to ensure the successful design and development of your electronics product. Each step on the list is essential to getting the job done.

Step 1: The primary design

This is the first, and perhaps the most important step in the process of developing your electronics project. In the primary design phase you need to focus on the product's production components, the cost required to complete the project, desired feature set and performance.

It's in this step itself that you determine whether your product is feasible, marketable and can be developed by you keeping within your production capabilities.

This is a high-level conceptual design phase, where you need to utilize block diagrams and individual components like microcontrollers to determine the workability of the project.

It's in this step that you also have to make an inventory of the components that you'll need to develop the device. Doing so successfully will allow you to evaluate the development cost.

Step 2: The circuit diagram

If the previous step was about developing a high-level design of the product, this one is all about the intricate details. In this step, you are required to develop a component-level circuit diagram that details how the different parts of the product will be connected.

This is a highly detailed and technical step and requires intense attention to individual circuit components and connections. One small mistake, an erroneous connection, and the entire project can be rendered dysfunctional.

The block-level circuit that you created in the previous step can come in handy here. Ideally, you should use specialized software to create separate sub-circuits for each block, and then interface them together to form the cohesive circuit in its entirety.

The outcome of this step will be the complete circuit diagram for your project. In every remaining step, this circuit diagram will be your faithful ally.

Step 3: Designing the PCB

After you've completed the detailed circuit diagram, now you need to design the Printed Circuit Board or PCB. The PCB is the physical platform that holds your actual physical components.

If you've been paying attention, then you know that the previous two circuit designs have been mostly conceptual. The PCB, however, is the first physical manifestation of your device.

Remember the software that you used to develop the circuit diagram? Usually, the same software can be used to create the PCB design.

Keep in mind: the more complex your circuit design, the more time and effort it will take to complete the PCB design.

Step 4: Determine the cost of fabrication

After you've completed the design of the PCB, you need to compile a complete estimate of the amount of money you'll require to fabricate the PCB. This should include the cost of individual components such as transistors, resistors, capacitors, etc.

Creating a complete cost estimate will help you to control the cost of manufacturing, and will also allow you to put in place a pricing plan as per your preferred profit margins.

Once the above steps have been completed to satisfaction, you now need to move on to the actual manufacturing part. That's exactly what we're going to focus on next.

Step 5: Fabricating the PCB

This is the step where you actually send the PCB design to the manufacturer for fabrication. The design files are usually generated by the software which you used to design the PCB.

Depending on your budget, you can send the designs to a small manufacturer for limited production. Or, if you want the benefits of batch fabrication you can give the contract to large scale fabricators.

Usually, in the case of electronic component design, the greater the numbers you print, the lower your cost per board.

Once the boards have been delivered, the next step is to solder on the individual circuit components onto the board. This process also can be automated by your manufacturer.

Step 6: The program and debug cycle

Once you have your prototype in hand, you'll need to test them out before programming. Usually, it's very rare for a prototype to function perfectly at first run. You'll likely need multiple iterations before you settle on the perfect instance.

This is the step where you'll be finding and correcting the bugs in your design. It's also the phase that can take the longest time and cost the most. Bugs are, by nature, unexpected anomalies, and you'll need to devote significant time and resources to figuring out their source and correcting them.

In tandem with the debugging and testing cycle, you'll also need to begin programming the microcontroller. The microcontroller is essentially the mind of your device, the unit that does all the logical processing. It's also the unit that controls the various parts of your circuit.

You'll need to be extra patient during this phase. Be prepared to encounter multiple errors and missteps. Don't worry, it's all part of the process.

Step 7: Develop the enclosure

At last, we are at the final step of our process: developing the enclosure. Wondering what that is?

The enclosure is the component that holds your entire device together. It's the chassis to your electronic wonder. Also, it's probably the first and only thing regular users are going to notice about your device.

Well, just think about it: you're certainly not going to hand over a bare-bones PCB to your users, are you? Nope, you need a sleek and stylish enclosure that can attract customers and get your product off the shelves.

Your enclosure can be made of plastics or metals, depending on your budget. For this, you can use 3D modelling principles, or even hire an industrial designer to get the ergonomics right.

However, if you think appearance isn't that critical to the success of your product, then you can hammer out a casing prototype using any available designing software. And then, it's simply a matter of 3D printing the same.

And you're done! You now have a fully functional electronics product in your hands!

But wait, how can you be expected to do all that by yourself?

Well, we never really said you'll have to, did we? In fact, you'll probably not be doing much of the steps yourself.

What you need here is a sound product development strategy that you can use to get the job done. That's exactly what we're going to discuss next.

Types of product development strategies to use

When you're setting out to tackle a new electronics product, getting the product off the drawing board and into the market can be a challenge.

However, it need not be; you just need to have a firm product development strategy in place. In the following sections, we are going to discuss a few product development strategies that you can apply to your development process.

Naturally, each has its own benefits, and there's no one size fits all solution to the problem. For the best results, we suggest you apply a combination of the best methods that suit your requirements.

The DIY approach

The complete DIY approach is not one that we advocate, for the simple reason that it's not possible for one person to handle all aspects of an electronics product development.

And yes, even if you are an engineer, the process can be a time consuming and cumbersome one. Because as you've already seen, the development process involves a plethora of activities such as digital design, PCB fabrication, and industrial designing. It's very rare that a single person will have all the required capabilities.

However, if you are one of those rare geniuses that can get the job done, then congrats! You're well on your way to save a decent amount of money.

Be advised, however, that the time that it would take to do everything yourself would increase your time to market. So for best results, we suggest hiring freelancers to take care of areas that are not part of your repertoire.

Which, in effect, brings us to our next point.

The freelancer route

If you are a non-technical person with the next best idea for an electronics product, you can't go wrong by hiring freelancers to take care of the job for you. Freelancers have the required expertise and experience to get the job done. Plus, they also cost a lot less than hiring a professional development firm (discussed next).

However, keep in mind that as an electronics product requires a diverse range of expertise, you'll likely have to hire a number of different professionals. This means you'll have to play the role of project manager and make sure that every freelance member of your team is working according to specifications and schedules. Or, you could make use of Freelancer's Technical Co-Pilot service to manage your project for you. Either way, it's important to hire the right freelancers for the right tasks. That means you'll want to look for freelancers skilled in:

Hire an external development firm

This is, of course, one of the simplest strategies to follow. But it's also one of the priciest. External development firms can charge an arm and a leg for complete product development.

If you are a startup, then there's another reason (apart from the money matters) why you shouldn't go for external firms. For any startup, it's important that it be intrinsically involved in the development of its products. Relying entirely on external developers reflects poorly on the company's ability to realize its vision.

Going with an overseas manufacturer

This used to be the dominant trend for lowering costs but actually comes with multiple caveats. For one, even though the manufacturer will offer you a relatively low price, they'll certainly require you to enter into an exclusive contract. This means when the time comes, you won't be able to shift to a cheaper option.

Also, by handing over your product details to a foreign manufacturer you risk losing your intellectual property rights. This can lead to a number of cheap knockoffs entering the market and undermining your share of the same.

Final words

Creating your own electronics product was once the stuff of big investments and could only be done by the large corporations. Today, however, with the help of freelancers, and technologies such as 3D printing and batch manufacturing, the costs and inhibitions have drastically come down.

This has enabled a large number of startups and independent inventors to bring their products to market. And due to the affordability of manufacturing, they've been able to pass on the benefits to the customer.

So, if you have a great idea for an electronics product, don't wait for someone else to take the cake. Get working on your idea, reach out to the required professionals and bring your dream to fruition.

Na tregoni çfarë ju duhet të kryeni

Fut emrin e projektit

Historitë e lidhura

Fol me një nga bashkëpilotët tanë për të të ndihmuar me projektin

Artikuj Të Rekomanduar Vetëm Për Ju

Launching a digital product like a web service or a mobile app can be scary. We'll show you the steps to success

18 min read

Businesses will increasingly have to turn to teams of freelancers to get work done. We'll show you the best way to manage them.

7 min read

The Coronavirus has severely disrupted the global logistics network. In this post we discuss the future of manufacturing and the transition process.

7 min read

Before you throw yourself into a new business idea, take a step back and ask yourself some tough questions.

5 min read

Faleminderit! Ne ju kemi dërguar me email një lidhje për të kërkuar kredinë tuaj falas.

Ndodhi një gabim gjatë dërgimit të email-it tuaj. Ju lutemi provoni përsëri.

Po ngarkohet shikimi paraprak

Leja u dha për Geolocation.

Seanca e hyrjes ka skaduar dhe ke dalë. Hyr sërish.